ZANPVC is your leading PVC compounds solution partner.

We always strive to be essential.

+86-18658459777

Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

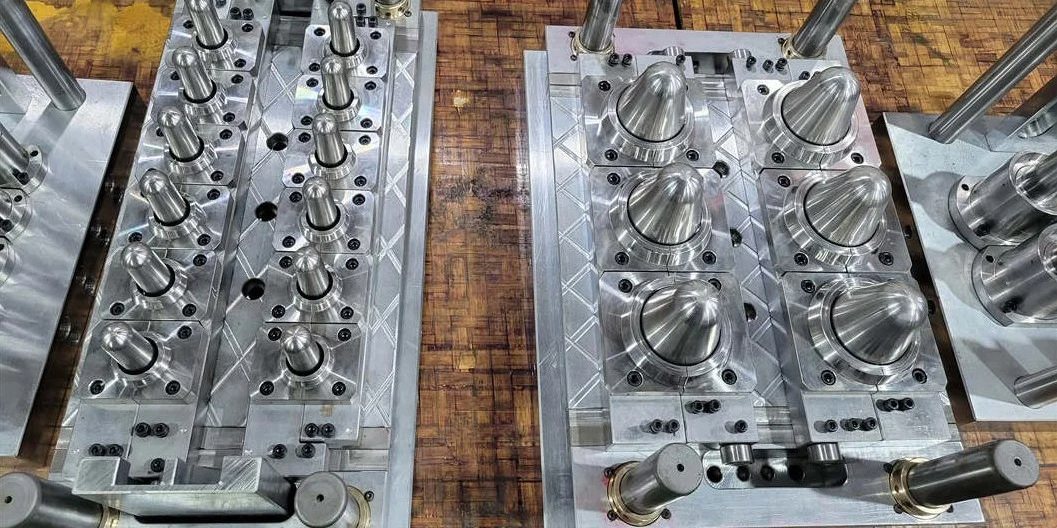

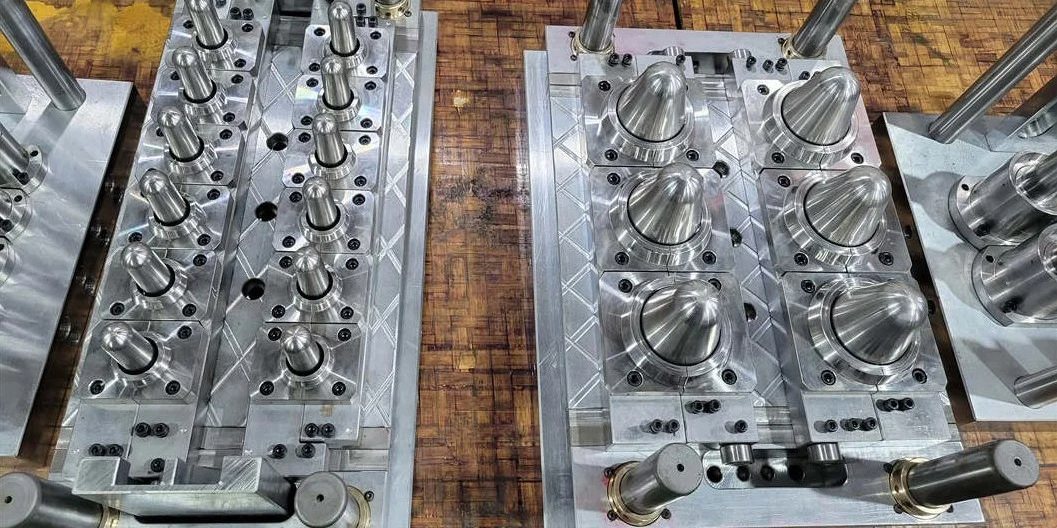

| Product name | 24mm Neck Pet Bottle Preform Mold |

| Neck size | 24mm,28mm,38mm, according to your request |

| Mould base | P20,Stainless steel |

| Cavity and core material | s136, etc. |

| Mold cavity | 1cav.-72cav. |

| Runner | Hot runner |

| Machine | 120-320T |

| Plastic material | PET |

| Mould life | 5-8 million shots |

| Delivery time | 50-65 days |

Our services

. Seller shall provide buyer all the technical documents relating to the product.

. Seller shall send buyer free sample of edible oil preforms for 2 times for product checking.

. Seller shall provide buyer the mould test video to see mould runningt status.

. Buyer shall support seller in sample and mould checking and give positive reply in technical problems.

Order Process For Mold

Stage 1

Make product design drawing as per original sample or customer's concept

Get machine specs from buyer

Plan mould specification

Stage 2

Make mould drawings according to the buyer's requirments & machine specs.

Approval of mould drawings by the buyer's

Stage 3

Order steel & standard parts and start machining work on core,cavity & mould base

Fitting,adjusting,polishing

Detailing & Assembly

Stage 4

First trial -To check mould injection dimensions, fittings and mark corrections

Second trial-Detailed inspection,corrections

Stage 5

Send mould testing video & photos to the buyer

Send trial samples by courier to customer and take approval

After do final corrections,do final trial-inspection

Stage6

Pack molds with wooden case

Delivery mould by sea or air

| Product name | 24mm Neck Pet Bottle Preform Mold |

| Neck size | 24mm,28mm,38mm, according to your request |

| Mould base | P20,Stainless steel |

| Cavity and core material | s136, etc. |

| Mold cavity | 1cav.-72cav. |

| Runner | Hot runner |

| Machine | 120-320T |

| Plastic material | PET |

| Mould life | 5-8 million shots |

| Delivery time | 50-65 days |

Our services

. Seller shall provide buyer all the technical documents relating to the product.

. Seller shall send buyer free sample of edible oil preforms for 2 times for product checking.

. Seller shall provide buyer the mould test video to see mould runningt status.

. Buyer shall support seller in sample and mould checking and give positive reply in technical problems.

Order Process For Mold

Stage 1

Make product design drawing as per original sample or customer's concept

Get machine specs from buyer

Plan mould specification

Stage 2

Make mould drawings according to the buyer's requirments & machine specs.

Approval of mould drawings by the buyer's

Stage 3

Order steel & standard parts and start machining work on core,cavity & mould base

Fitting,adjusting,polishing

Detailing & Assembly

Stage 4

First trial -To check mould injection dimensions, fittings and mark corrections

Second trial-Detailed inspection,corrections

Stage 5

Send mould testing video & photos to the buyer

Send trial samples by courier to customer and take approval

After do final corrections,do final trial-inspection

Stage6

Pack molds with wooden case

Delivery mould by sea or air