ZANPVC is your leading PVC compounds solution partner.

We always strive to be essential.

+86-18658459777

Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

| Brand Name: | ZANPET |

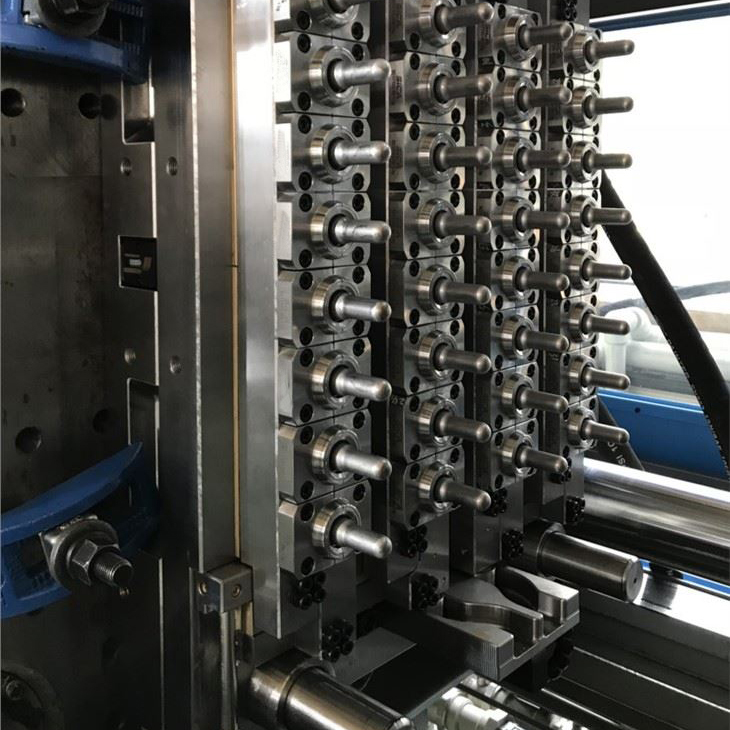

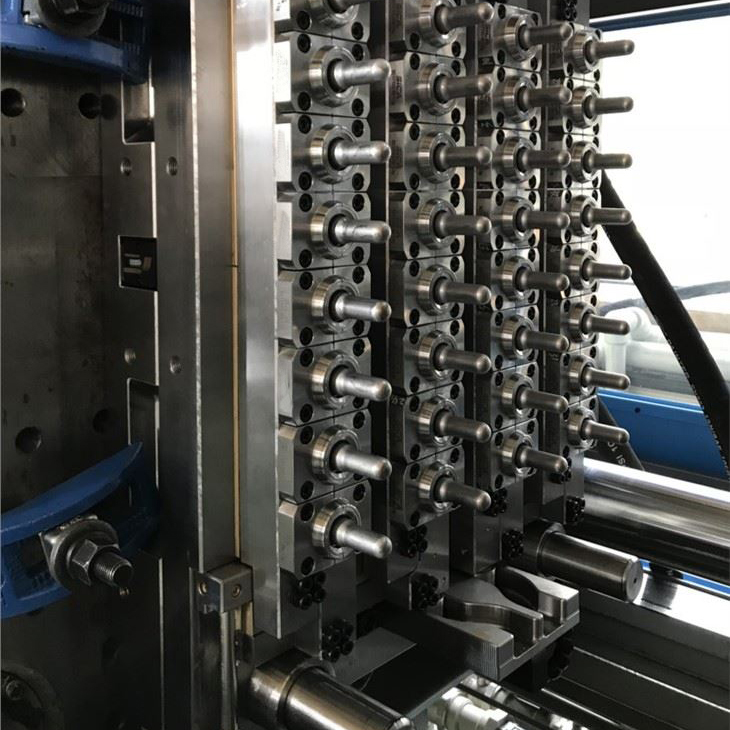

| Product Name: | Cosmetics Bottle Preform Mold |

| Shaping Mode: | Injection preform mould |

| Product Material: | S316 Steel |

| Runner: | Hot runner valve gate |

| Plastic material | PET |

| Cycle time: | 11-20S |

| Mould life time: | 5-8 million shots |

| Lead time: | 50-65 DAYS |

| Software: | UG,CAD,CAM,CAE,PR-E |

| Tooling machine: | CNC,CNC lathe, EDM , Engraving ,Wire-Cutting |

| Place of Origin: | Zhejiang, China |

OUR PET Preform Mould Feature

1.Hot runner production, save labor cost. One worker can work for 3 or 4 sets of injection machine

Large diameter pipe make the mould cool fast and well. Shorten cycle time.

2.Adopt double ejection device, pulley sliding and ejector sleeve to make sure the preform can be ejected smoothly without the robot hand.

Use P20 pre-hardened steel as the PET preform mould plate to make complete structure stable, not easy transformation.

3.All the mould plate rust-proof handling, decrease the second pollution during the production.

Core, cavity and screw all use S136 stainless steel. After the vacuum treatment, hardness 48-50HRC.

Guarantee: 5 million shots.

4.Core, cavity and neck screw is controlled by the double cone positioning to ensure does not appear flash, different size, irregular and other defects.

FAQ

Q1: Where is your factory?

A: We locate in Taizhou, Zhejiang, China mainland.

Q2. How can I get the accurate price ?

A.There are some basic specs we need to know for price calculate, that are: 3D drawings in STP,IGS,X-T format are avaialble, 2D drawings with tolorance or requirements, Please suggest us your quantity too.

Q3. How do I pay for the order?

A.The common payments are T/T(Telegraphic Transfer),L/C, papal etc.

Q4. Do you accept the OEM?

A. OEM is welcome. We can custom the good according to your design.

Q5. Can I test my idea/component before committing to mould tool manufacture?

A. Yes, we can use CAD drawings to make a prototype parts for testing and functional evaluations before the standard mold making.

Q6. What type of mould tool do I need?

A. Mould tools can be either single cavity (one part at a time) or multi-cavities(2,4, 8, 16 up to 64 parts at a time). Single cavity tools are generally used for small quantities, up to 20,000 parts per year whereas multi-cavities tools are for larger quantities. We will suggest a best choice from your projected annual volume requirements and recommend a optimal solution for save your money and time.

| Brand Name: | ZANPET |

| Product Name: | Cosmetics Bottle Preform Mold |

| Shaping Mode: | Injection preform mould |

| Product Material: | S316 Steel |

| Runner: | Hot runner valve gate |

| Plastic material | PET |

| Cycle time: | 11-20S |

| Mould life time: | 5-8 million shots |

| Lead time: | 50-65 DAYS |

| Software: | UG,CAD,CAM,CAE,PR-E |

| Tooling machine: | CNC,CNC lathe, EDM , Engraving ,Wire-Cutting |

| Place of Origin: | Zhejiang, China |

OUR PET Preform Mould Feature

1.Hot runner production, save labor cost. One worker can work for 3 or 4 sets of injection machine

Large diameter pipe make the mould cool fast and well. Shorten cycle time.

2.Adopt double ejection device, pulley sliding and ejector sleeve to make sure the preform can be ejected smoothly without the robot hand.

Use P20 pre-hardened steel as the PET preform mould plate to make complete structure stable, not easy transformation.

3.All the mould plate rust-proof handling, decrease the second pollution during the production.

Core, cavity and screw all use S136 stainless steel. After the vacuum treatment, hardness 48-50HRC.

Guarantee: 5 million shots.

4.Core, cavity and neck screw is controlled by the double cone positioning to ensure does not appear flash, different size, irregular and other defects.

FAQ

Q1: Where is your factory?

A: We locate in Taizhou, Zhejiang, China mainland.

Q2. How can I get the accurate price ?

A.There are some basic specs we need to know for price calculate, that are: 3D drawings in STP,IGS,X-T format are avaialble, 2D drawings with tolorance or requirements, Please suggest us your quantity too.

Q3. How do I pay for the order?

A.The common payments are T/T(Telegraphic Transfer),L/C, papal etc.

Q4. Do you accept the OEM?

A. OEM is welcome. We can custom the good according to your design.

Q5. Can I test my idea/component before committing to mould tool manufacture?

A. Yes, we can use CAD drawings to make a prototype parts for testing and functional evaluations before the standard mold making.

Q6. What type of mould tool do I need?

A. Mould tools can be either single cavity (one part at a time) or multi-cavities(2,4, 8, 16 up to 64 parts at a time). Single cavity tools are generally used for small quantities, up to 20,000 parts per year whereas multi-cavities tools are for larger quantities. We will suggest a best choice from your projected annual volume requirements and recommend a optimal solution for save your money and time.